- This topic is empty.

-

AuthorPosts

-

2025-10-13 at 5:38 pm #13919

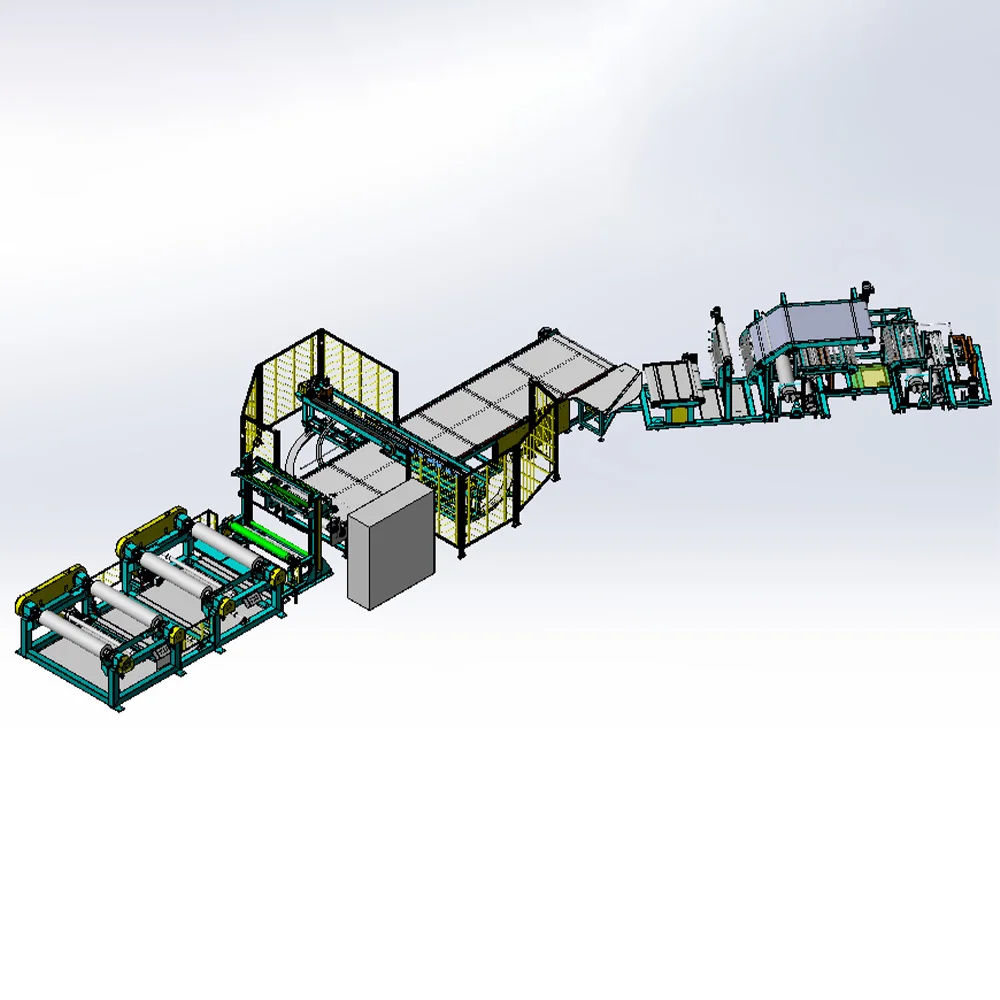

The tire manufacturing industry constantly seeks equipment that balances precision, efficiency, and safety. Among these, the tire bias cutting machine plays a crucial role in shaping the raw tire components with accuracy. Unlike radial tire production, bias tires require careful alignment of plies, demanding advanced machinery to meet modern production standards. In this blog post, as a high quality tire manufacturing machine factory, SONIWELL will share the importance of tire bias cutting machine in manufacturing.

Evolution of Tire Bias Cutting Machines in Manufacturing

The evolution of tire bias cutting machines has been driven by the need for higher precision and faster production rates. Early machines relied on manual operation, which limited speed and consistency. Modern designs incorporate automated feeding systems, computer-controlled cutting, and adjustable cutting angles to optimize the alignment of bias plies. These advancements have not only improved quality but also reduced material waste, ensuring more sustainable operations.

Precision Control in Bias Tire Ply Cutting

A critical aspect of bias tire ply cutting is precision. The ply layers must be cut to exact dimensions to ensure proper tire performance. Advanced tire bias cutting machines utilize digital control systems that adjust the cutting head dynamically, compensating for material elasticity and thickness variations. This ensures uniform cuts across multiple tires, improving the overall consistency of the final product.

Integrating Safety Measures in Tire Cutting Operations

Safety is paramount in tire production due to the high-speed moving parts involved. Modern tire bias cutting machines are equipped with protective barriers, emergency stop systems, and automated sensors that detect misalignments or material jams. These safety features reduce workplace accidents while maintaining continuous production, an essential factor for large-scale manufacturing facilities.

Material Optimization and Waste Reduction

Efficient use of rubber and reinforcement materials is a core focus of tire bias cutting systems. By precisely aligning the cutting path with the tire ply layout, manufacturers can minimize offcuts and optimize material consumption. Some machines are also capable of automatically sorting usable scraps, which can be recycled or repurposed for other products, contributing to a circular economy in tire production.

Automation and Digital Control in Modern Machines

Automation has redefined the efficiency of bias tire cutting processes. CNC-based systems allow operators to program cutting patterns with high accuracy. Integration with production management software enables real-time monitoring of cut length, angle, and ply orientation. These digital capabilities reduce human error, streamline operations, and provide traceable records for quality assurance purposes.

Maintenance and Longevity of Tire Bias Cutters

Maintaining a tire bias cutting machine is essential for long-term performance. Routine inspection of cutting blades, calibration of digital sensors, and lubrication of mechanical components ensure consistent results. Some machines feature predictive maintenance modules that alert operators to potential failures before they occur, preventing costly downtime and extending machine lifespan.

Customization for Different Tire Specifications

Tires vary in size, ply number, and material composition. Modern bias tire cutters offer adjustable cutting angles, blade types, and feed mechanisms to accommodate different specifications. This flexibility allows manufacturers to produce a wide range of tires without investing in multiple machines, enhancing production versatility and cost efficiency.

Environmental and Energy Considerations

With increasing emphasis on sustainability, tire bias cutting machines are designed to consume less energy and minimize environmental impact. Energy-efficient motors, low-friction components, and optimized cutting cycles reduce electricity consumption. Additionally, some systems incorporate dust and vapor collection units to maintain a cleaner work environment and reduce pollution.

Future Trends in Bias Tire Cutting Technology

The future of bias tire cutting technology will likely involve greater AI integration, predictive analytics, and enhanced automation. Machines may soon adapt cutting patterns in real time based on tire material behavior, reducing defects and further increasing efficiency. The convergence of robotics, digital monitoring, and sustainable design will continue to shape next-generation tire manufacturing.

Conclusion

The tire bias cutting machine is more than just a component of the production line; it represents a convergence of precision engineering, automation, and sustainability in tire manufacturing. By embracing modern technology, manufacturers can achieve higher quality, reduce waste, and ensure safety while meeting the growing demand for bias tires worldwide.

http://www.soniwellgroup.com

SONIWELL -

AuthorPosts

- You must be logged in to reply to this topic.